[ad_1]

When you think of a head-on collision between two cars, what comes to mind? Screeching tires, mangled metal, a world of hurt, and hopefully survival due to optimized crumple zones and strong safety cells, right? What about when you think of a crash between two electric cars? Well, as Mercedes is demonstrating with a new crash test between an EQA and an EQS SUV, it’s… pretty much the same.

“Mercedes-Benz electric vehicles are every bit as safe as all other models from the brand with the star,” reads the brand’s press release headline. Still, let’s watch some EVs crash head-on with one another, shall we? Maybe we’ll learn something.

![]()

Mercedes’ test is like a choreographed dance of airbags, crumpled metal, and seatbelts – all set to a dramatic music score. It’s the kind of crash you’d want to watch with a bag of popcorn (from a safe distance, of course). See this epic video I put together from their press footage below.

Going the Extra Mile (Per Hour)

Euro NCAP says, “Hey, let’s crash-test a car at 31 mph,” and Mercedes-Benz responds with, “That’s cute, but how about 35 mph?” Not only did the company add a couple of miles to the industry’s standard frontal impact test, but it used as a crashing-device a real car instead of the usual trolley with a honeycomb barrier.

We’ve seen some similar tests conducted by the Insurance Institute for Highway Safety, with the most famous one being 1959 Chevy Bel Air vs. 2009 Chevy Malibu:

Like all electric SUVs, the Mercedes’ EQA and EQS are no lightweights at 4,800 and 6,600 pounds, respectively. That’s the heavyweight bout of the century, and the collision energy was off the charts! A quarter century ago, such big and heavy SUVs might have crumpled and twisted like a pretzel, but the new Mercedes’ passenger safety cells stayed as secure as a vault, and the doors still opened after the test. That means if you ever find yourself in a pickle, then you can probably just wiggle out of the wreckage or let the heroic first responders reach you.

Oh, and also critical to EV crash tests is the fact that the high-voltage systems shut off automatically; first responders are probably going to be very thankful for that given the trouble fire departments have had putting EV fires out.

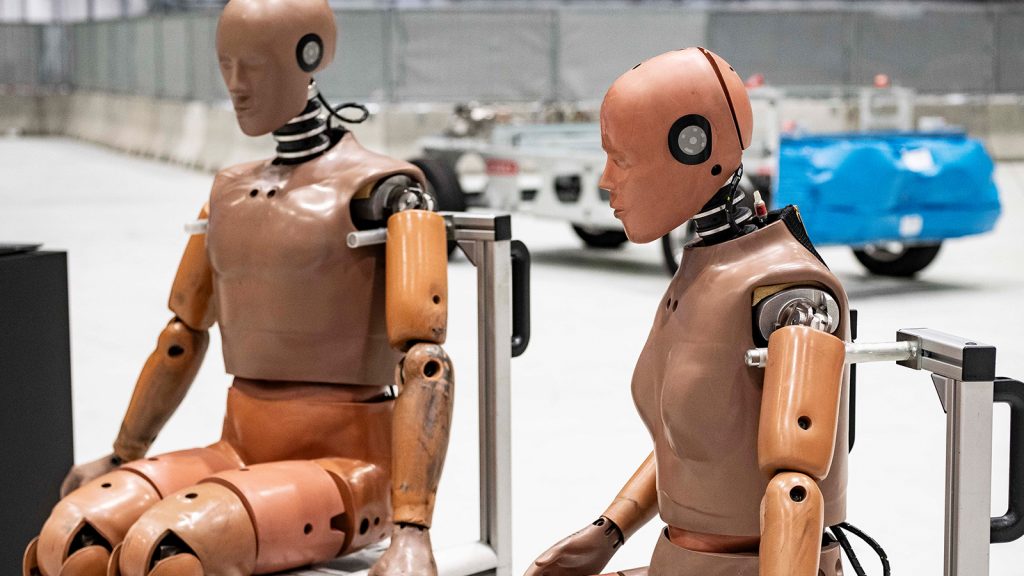

Mercedes talks about why 108 pound, 4 foot 11 crash dummies were used in the driver’s seats of each car:

Another focus of the crash test was the type of dummy that the safety experts placed in the driver’s seat of both vehicles – the Hybrid III 5th Percentile Female, which is the female dummy currently used in the automotive industry for frontal collision tests. It corresponds to a woman of approximately 1.5 meters tall (4 feet 11 inches tall) and weighing around 49 kilograms (108 lbs). According to the underlying statistics, only five percent of women worldwide are smaller or lighter. For many years, Mercedes-Benz has used frontal crash tests with fifth percentile female dummies1 in the front seat to design its protection systems for the widest possible range of customers. Ratings by consumer protection associations as well as various legal requirements worldwide now include specifications for testing with fifth percentile female dummies. Another fifth percentile female was a passenger in the EQA. In the passenger seat of the EQS SUV was a Hybrid III 50th Percentile dummy, representing a 78-kilogram (172 lbs) male of average height.

High-Voltage Safety

Mercedes breaks down its high-voltage safety hardware in its press release, writing:

Mercedes-Benz has developed a multi-stage high-voltage protection concept for its electric vehicles. The system has eight key elements to ensure the safety of the battery and all components with a voltage above 60 volts. Examples include separate positive and negative wiring and a self-monitoring high-voltage system that automatically switches off in the event of a serious collision.

[Editor’s Note: I’m a little baffled by the “separate positive and negative wiring” thing, because doesn’t pretty much any electronic device have separate positive and negative wiring? If you don’t, that’s how you get short-circuits. My guess is they mean the positive and negative lines are well-isolated, so in a crash they don’t ground together and short out and turn those wires into a heating element. I think? – JT]

So, what have we learned today? Mercedes-Benz’s head-on collision of two electric vehicles apparently signifies a technological milestone (” the world’s first public crash test involving two fully electric vehicles,” per Mercedes), and also your next dream vacation should be to their Technology Centre for Vehicle Safety in Sindelfingen. With a full roster of crunchy machines, they perform up to 900 crash tests and 1,700 sled tests annually. Bring the popcorn.

[Ed Note: OK, so this post was mostly done because 1. We wanted to add a video to our video player, which we’re still populating and 2. Watching cars crash is fun and 2. Plus, there actually is some gold in here. First, check out Mercedes’ own video:

I mean, come on! Look at this beautiful screenshot of the simulation Mercedes did for the crash test between the two vehicles. You can bet engineers did some Finite Element Analysis (which is defined by CAD software developer AutoCAD as “a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects”):

It’s cool to see the individual components in the crash; I see seats, cooling modules, an air conditioning compressor, ABS pumps — let us know what you see.

There’s also this little nugget from Mercedes passive safety engineer Julia Hinners, explaining why cars are often painted Orange for crash tests:

“We take this orange color because, when we first started doing crash tests, it was just black and white filming, and on the black and white films, this orange color was the best contrast.”

Huh… after seeing scores of orange-painted-car crash test, I’d never thought of that. I did a bit of research and found that Danish engineering firm Bruel and Kjaer did a writeup on Volvo’s then-new Volvo Cars Safety Center in Sweden (this was around the year 2000). Here’s what the writeup says about orange paint:

[Test engineer at Volvo’s safety center] Patrik Settergren explains, “Each test car is a full production model, exactly as it would be seen by a customer”. He continues, “We have a special preparation area where around 25 people are employed and it takes us about 10 days to prepare each car.” Volvo paints it’s test cars matt orange. We have found that this is the best colour for filming the tests as it gives clear pictures from the high speed cameras”.

[…]

Patrik says, “The digital cameras record the crash at 1000 frames a second. We also position cameras on the ground and under glass floors to document the underside of the car during a crash. We use special high-power lamps which simulate daylight and we have found that the orange paint reduces reflections from the lamps and gives the best results.”

Fascinating stuff! -DT]

[Note: Therese is a fantastically capable video editor and process-improvement specialist. As this was her first story for The Autopian, the piece was co-written by David Tracy.]

[ad_2]